Energy Sector

consulting since 2017.

Starting 2022 service, spare parts for turbines and power units.

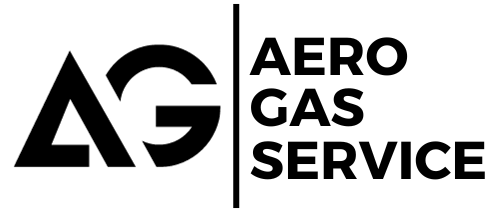

Maintenance of turbines

Service features:

- — Inspection of the power unit and TURBINE is performed every four thousand hours of operation, but at least once a year

- — The decision on the need for repairs is made on the basis of the actual technical condition of the equipment based on the results of inspections performed

- — Service intervals do not depend on the number of unit starts: there is no need to calculate equivalent operating hours (for peak operation it needs to be specified).

- — Possibility to replace/exchange hot modules (medium repair) at the customer’s site

- — Possibility to perform turbine overhaul by its replacement at the Customer’s site without removal of the turbine to the repair shop: multiple reduction of the time of scheduled shutdowns related to turbine overhaul

- — Easy transportation

- — Repairs are carried out in specialized service centers: significant reduction of the risk of the Customer not having the necessary spare parts, tools and necessary specialists during repairs

- — Ability to fix prices for scheduled repairs when agreed hours of operation are reached, regardless of the number of rejected parts to be repaired.

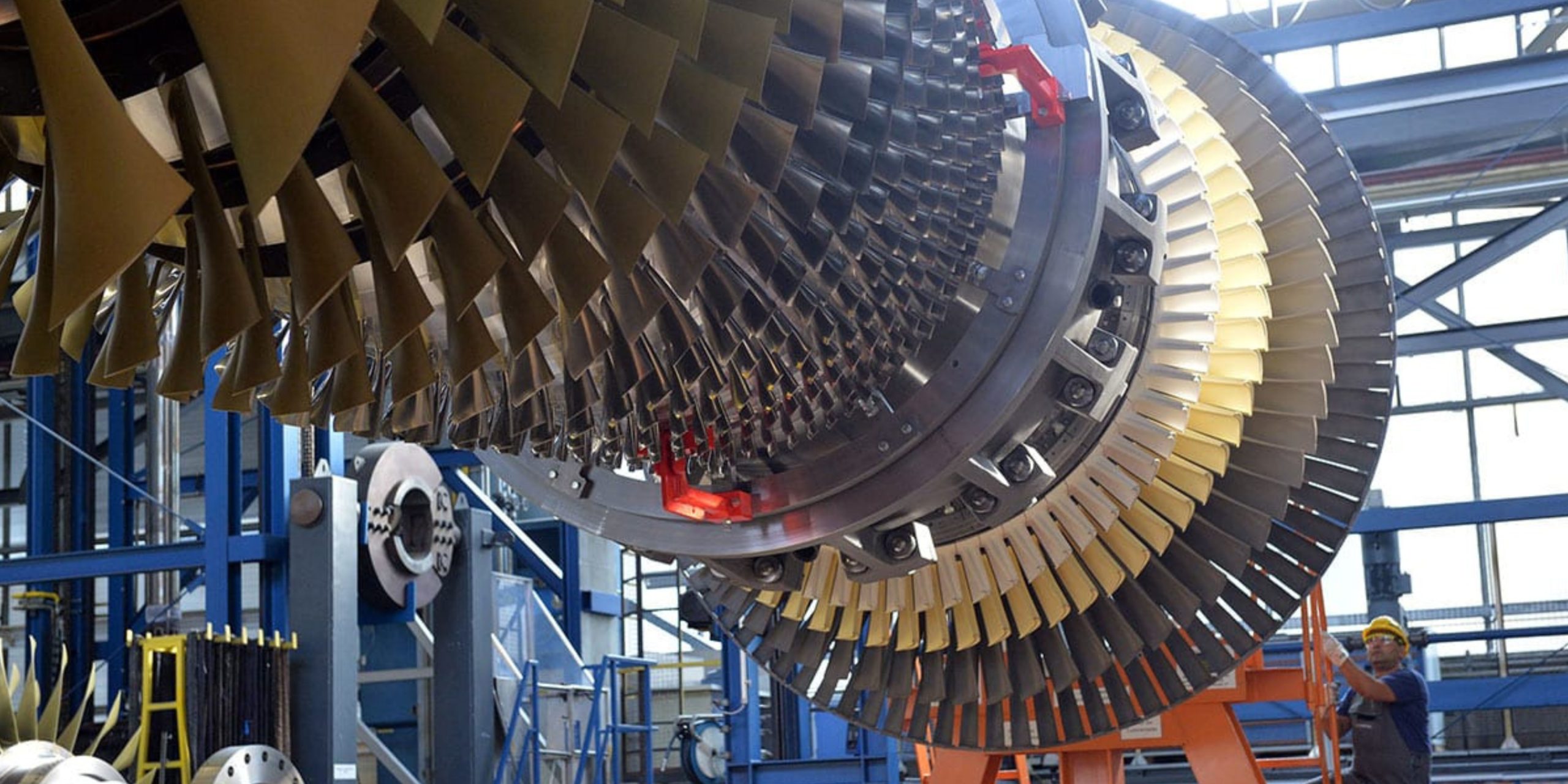

Service Center:

— Spare parts warehouse for operational support of customers in case of unplanned shutdowns. The volume is formed under contract

— Tool storage for Level I and II maintenance (e.g., HF module replacement, boroscoping, Level 2 hot part repairs, preservation, minor HT repairs)

— Storage of leasing turbines

Repair shop capabilities include:

— transportation platforms

— crane equipment according to specification

— sets of specialized tools for each type of turbine for engine disassembly in the scope of replacement of the PM modules

— specialized tool for level 2 work

Long-term full service contracts

Scheduled and Unscheduled maintenance of power units under one Contract, as well as performance of additional works

Allows to significantly improve the accuracy of budgeting of service costs

In case of inclusion of coverage for unscheduled events in the contract: optimization of expenses for unscheduled repairs

Focus on optimizing the performance of systems and equipment

Guaranteed scope of work -> localization + personal approach to the Customer

Ability to provide guarantees of equipment availability and its planned degradation

Scope of Work

1.Scope of planned work with a fixed price for each unit of serviced equipment performed at the customer’s site:

— Inspection of power unit boroscopic inspection of turbine for each unit of serviced equipment every 4 thousand hours of operation or once a year

— Seasonal adjustment of the combustion chamber of the Gas Turbine

— Annual inspection of the fire extinguishing system

— Annual gearbox inspection

— Annual generator inspection

— Replacement/repair of KVD rotary vane bushings

— Replacement of 3, 4, 5 stage AHF blades

— Replacement of first stage AHV blades, inspection of AHVs of stages 2-4 after 25000 hours of SPRINT system operation.

— Replacement of the Hot End and Combustion Chamber Modules as part of the HF Module Repair including dismantling/assembly of the turbine and pre-startup.

— Replacement of turbine s under overhaul including dismantling/mounting of turbine s and pre-launch commissioning.

2.Fixed price scope of work in Repair Shop Level 4 with access to vendors performing scope of work requiring the use of licensed technologies:

— Scheduled Repair of turbine

— Scheduled Overhaul of turbine

3.Unscheduled and additional work: calculated at the Hourly rates and rates for used spare parts and materials valid at the time of work performance. This type of work can be performed either at the Customer’s site or in the repair shop depending on the scope and type of work

4.Non-reducible production inventories

Structure of the service agreement

— Spare parts warehouse for operational support of customers in case of unplanned shutdowns. The volume is formed under contract

— Tool storage for Level I and II maintenance (e.g., HF module replacement, boroscoping, Level 2 hot part repairs, preservation, minor HT repairs)

— Storage of leasing turbines

Repair shop capabilities include:

— transportation platforms

— crane equipment according to specification

— sets of specialized tools for each type of turbine for engine disassembly in the scope of replacement of the PM modules

— specialized tool for level 2 work

Energy Aero Services' subject matter experts:

5 Russian service engineers to perform work at Customer sites in the Russian Federation

2 service managers (conclusion and execution of contracts)

1 specialist in safety, work planning and organization and human resources management (service engineers)

1 specialist in spare parts, record keeping and reporting

1 specialist in maintaining the tool fleet, its verification and delivery of tools to the sites

2 engineers — Level 2 works are performed by specialists from the existing engineers, there is no need to keep additional personnel. Level 4 works are not economically feasible only for the Russian fleet.

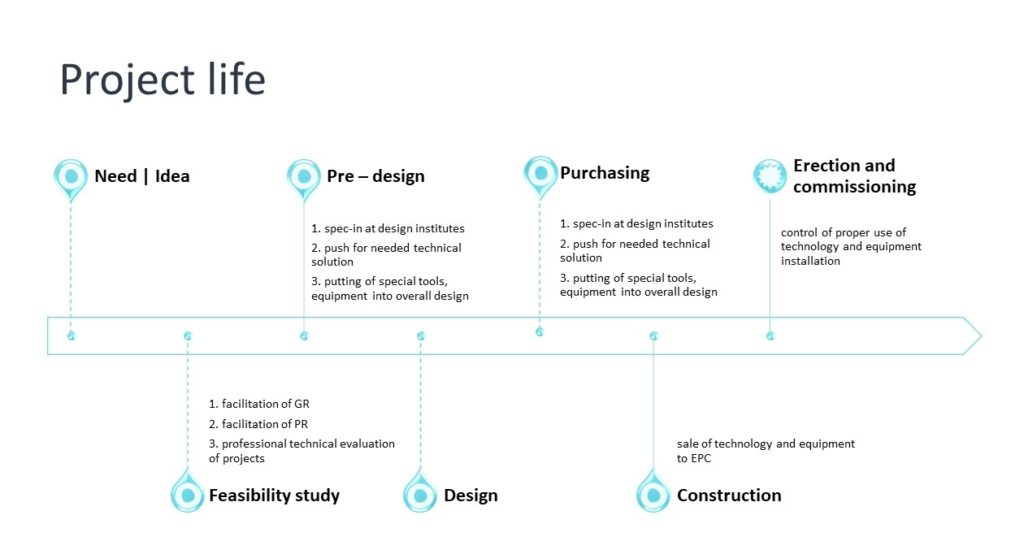

Turnkey solution for engineering

Aero Gas Service provides turnkey solution for engineering / technical clients willing to successfully access EMEA markets or to boost their sales and business in the region.

Thanks to the fact it was possible to unite many professionals under the same brand, an aggregator of qualifications was created and an exceptional opportunity to consider completely new industries for work was obtained.

The company’s specialists have excellent knowledge of EMEA markets for engineering projects, production set up, product sales.

The company also operates in such sectors as:

— Conducting an independent examination of the design and estimate documentation (to assess the economic feasibility of the project).

— Examination of project documentation and engineering survey results

— Support of investment projects, construction projects and works

— Due Diligence

Solutions

— Soil improvement engineering

— Special machinery supply for soil improvement

— HV Electric engineering automation, protection, and control

— Industrial Electrical, electromechanical solutions and products supply

— Electric energy systems production, engineering, and installation

- Renewal: hydrogen, solar, hydro, wind

- Convention: gas, diesel, methanol

— Energy supply turnkey solutions (rental + sales)

— Water treatment technologies, wastewater treatment

— Waste processing, recycling

— Industrial gases filtration

Realized Projects

Types of projects:

1) Implemented in project design and deep soil mixing technology — around 2,2 million m3 + supply special machinery

2) Spec-in and supply of special electrical equipment for nuclear power plants — around 300 million dollars

3) Sales of ferroalloy up to 5000 tons per month

4) Spec-in and sale of HV electrical equipment for Power Generation and National Grid — more than 1 billion dollars since 2009

5) Merge and acquisition deals facilitation for industrial companies in Power, Mines&Metals — more than 200 million dollars

6) Industrial drones’ production and sales, and operation in agriculture civil operations, and Oil&Gas

7) Production location of gas engines and generators sets up to 50 kw. Sales of gas generator sets and electricity

Countries:

Egypt

India

Bangladesh

United Arab Emirates

Saudi Arabia

Kazakhstan

Uzbekistan

Tajikistan

Kyrgyzstan

Ukraine

Macedonia

Bosnia

Italy

Georgia

Germany

Austria

France

Finland

Azerbaijan

Turkey

Hungary

Ghana

Russia

Nigeria

Contacts

- +7 965 440-70-00

- info@aerogasservice.ru

- 123112, Moscow, nab. Presnenskaya, 10, office 558